Disclaimer

The Dover Public Library website offers public access to a wide range of information, including historical materials that are products of their particular times, and may contain values, language or stereotypes that would now be deemed insensitive, inappropriate or factually inaccurate. However, these records reflect the shared attitudes and values of the community from which they were collected and thus constitute an important social record.

The materials contained in the collection do not represent the opinions of the City of Dover, or the Dover Public Library.

The Cloth Manufacturing Process--3. Carding

An interview with Robert B. Marnoch, Overseer of Carding, No. 1 Mill

Cocheco Chats, November 1921

The Cotton comes to the Card Room in the form of a lap. In the Picker Room most of the heavier dirt and seed was taken out. So the cotton as it comes to the Card contains, besides the good fibre to be manufactured, small bits of leaf, tangled knots of fibre and short fibres. It is the duty of the card to remove these undesirable elements, so that the cotton that goes forward will contain only those fibres that will make even yarn and perfect cloth.

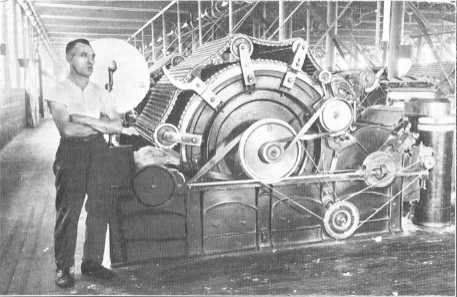

Grinder Desire Nadeau Standing Beside Card

There are five principal parts to the card: Lickerin, cylinder, flats, doffer and coiler. The lickerin is covered with coarse teeth; the cylinder, flats and doffer are covered with hundreds of thousands of fine wire points; the coiler is a device for delivering the cotton. The lap is unwound and fed to the lickerin, which removes those of the heavier impurities that by some chance escaped the picker. From the lickerin it is transferred to the cylinder and carried by the points of the wire on the cylinder past the wire on the flats. This produces an action on the fibres similar to that of combing the hair and removes the remaining impurities, tangled knots and short fibres. The doffer takes the fibres from the cylinder and carries them to the front of the card and condenses them into the form of an untwisted rope, known as sliver. This sliver is coiled in a can, this being a convenient form for the next process.

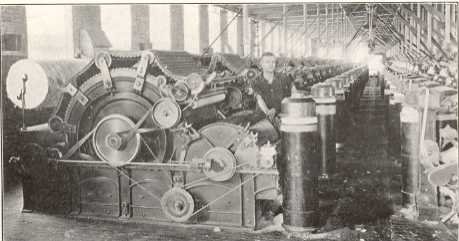

Card strippers tend the cards. These men strip the cards daily; that is, they removes the waste that has become embedded in the wire of the card; oil the cards; keep them clean; feed them with laps and remove the cans of sliver as they become full. The cleanliness of the card depends upon these men. Inasmuch as the primary purpose of the card is to clean, any failure to keep the machine clean and in good running order prevents them from doing their work. Carding is the last of the cleaning processes, and any impurities that pass through will be felt at every succeeding proceeding, and will show in the cloth.

A line of Cards in No. 1 Mill, Stripper Felix Gardner at Work

The different parts of the card are set very nicely. Especially where the wires on the cylinder, flats and doffer come near each other, the settings are made exact to a thousandth of an inch. Upon the accuracy of these settings depends to a large extent the quality of the work done by the machine. The grinders, each of whom has general charge of a section of cards, attend to this matter of setting, personally. The grinders also periodically grind the points of the wire with emery to keep them sharp and able to clean properly. The work of the grinder is exacting, and to the extent that he does his work carefully and well is the mill able to produce a high quality of cloth.

This historical essay is provided free to all readers as an educational service. It may not be reproduced on any website, list, bulletin board, or in print without the permission of the Dover Public Library. Links to the Dover Public Library homepage or a specific article's URL are permissible.